Air technology enables CLAAS to put agricultural machinery through its paces

Before a combine harvester rolls off the production line, it is tested under realistic conditions. It goes without saying that this is a noisy process - but modern, high-tech production designed for digital agriculture must not suffer as a result. At premium manufacturer CLAAS, Kappa has implemented a pioneering solution for the cab, air, sound and lighting technology of the test stations.

Future-proof air technology for combine harvester test station

Founded in 1913, the family-owned company CLAAS is one of the world's leading manufacturers of agricultural technology - the company produces combine harvesters, forage harvesters, tractors, agricultural balers and grassland harvesting machines. The innovative agricultural equipment is equipped with state-of-the-art information technology - the machines are pioneers for the age of “digital farming” and fit for Agriculture 4.0.

The company's main plant in Harsewinkel, Westphalia, has been producing combine harvesters since 1936. To date, over 450,000 of these harvesters have rolled off the production line there. Since the restructuring of the plant in 2003, the factory in Harsewinkel has been one of the most modern production facilities for combine harvesters and forage harvesters in the world. Intelligent production processes and logistics ensure optimum machine utilization.

The challenge

CLAAS has set a new course with the SynPro 2020 modernization and investment programme. The SynPro 2020 project was primarily about mapping the production of the two assembly lines for combine harvesters on one line. This will increase efficiency and flexibility without compromising on quality. The latest, future-proof test bench technology is used to test the machines. Function and performance are subjected to comprehensive testing under realistic conditions. All systems and components of a combine harvester are tested and recorded.

The solution for future-proof test stand technology - clean, bright and quiet

Test benches are primarily used for quality control before the agricultural machinery is delivered. Practical conditions are simulated and all functions are systematically tested, analyzed and recorded.

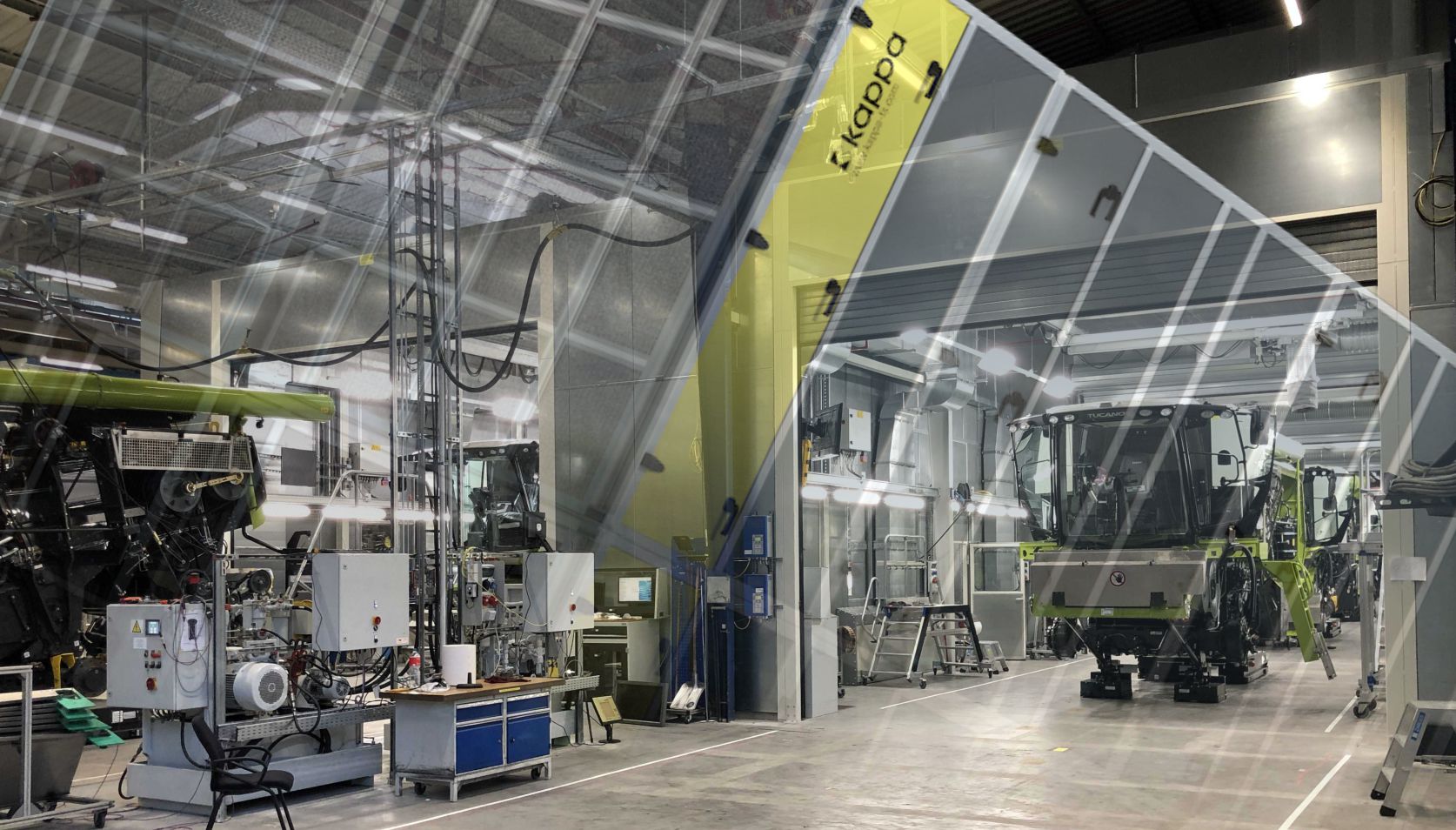

Two parallel and synchronous test cabin lines were developed at the factory. Each test cabin line consists of three individual cabins, which the agricultural machines pass through one after the other. Air technology specialist Kappa implemented the entire cabin, air, sound and lighting technology.

The realistic testing of the vehicles causes a lot of noise, exhaust fumes and waste heat. The test cabins were therefore equipped with a comprehensive sound insulation concept. It prevents the noise from radiating into other areas of the hall. Hazardous diesel emissions are also produced during the test. These are captured directly by linear, and therefore freely positionable, exhaust extraction devices on the top of the test cabin and discharged from there.

Diffuse emissions, fine dust from abrasion and waste heat are removed via controlled ventilation of the test cabin. The booths and all work areas are supplied with conditioned fresh air. It flows in above the cabin floor, while fugitive emissions and waste heat are dissipated from the cabin ceilings. These measures make it possible to ensure the quality of the products while at the same time guaranteeing occupational safety for all employees.

Clean thanks to efficient ventilation and extraction

To capture the emissions produced, each cabin is equipped with an independent, state-of-the-art ventilation system. The type of air supply in the cabin is decisive for the working climate in the cabin.

Air currents at fuselage and head height of the employees must be avoided, as they are perceived as disturbing. For this reason, Kappa diffusers were installed on the cabin floor to ensure a draught-free introduction of air into the cabins. The uniform arrangement of the diffusers in the floor area of the cabin ensures an even flow of air through the cabin from bottom to top, and the emissions released are directed under the cabin roof, where they are extracted.

Bright thanks to a reliable lighting concept

The cabins have been fitted with large viewing windows. This allows natural light to enter the cabins, giving the room a spacious feel. The modern lighting technology meets all ergonomic requirements: all work areas are optimally illuminated, which ensures pleasant and fatigue-free working and reduces the error rate.

Quiet thanks to comprehensive sound insulation

The test cabins are soundproof cabins with dimensions of 39.0 (L) by 20.6 (W) by 6.3 meters (H). The entire cabin was divided into segments on the two lines with three test cabins each and are equipped with roller shutters, doors, windows, partition walls and comprehensive technology packages.

The cabins have a perforated surface on the inside that largely absorbs sound emissions. This reduces the unpleasant reflection of noise that occurs on smooth surfaces.

Outstanding energy efficiency thanks to intelligent design and automation

The cabins are controlled individually and therefore according to demand. In full-load operation, the entire air output is available; in partial-load operation, the air volume is reduced. The required air flow is automatically adjusted to the load found. The exhaust extraction system is decoupled from the cabin ventilation system and is also load-dependent. The adaptation to the respective power requirement ensures high savings in electricity costs.

The waste heat from the cabins is recovered via highly efficient heat exchangers and used to heat the cabin supply air. This considerably reduces the energy required to heat the fresh air. The waste heat from the exhaust air is used to heat the cabin supply air.