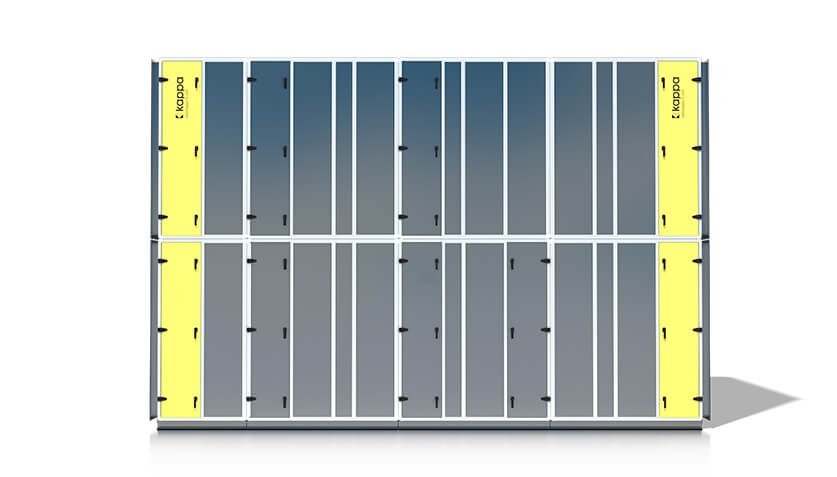

Energy recovery,

heat recovery

Due to the production-related thermal streams, a considerable amount of waste heat is usually dissipated with the industrial exhaust air. The Kappa MTATM systems enable a complete integration of a high-quality heat recovery module.

The high degree of filtration of the - usually upstream - exhaust air filter stages makes it possible to use heat exchangers with a high degree of efficiency. The efficiency of heat recovery can be maintained at a consistently high level even in the toughest industrial applications. The heat recovery modules of the Kappa MTA™systems enable the complete integration of a high-quality heat recovery module.

Systems are cleaned automatically using compressed air flushing and high-pressure water jets.