Steinbach protects employees and thus ensures significantly improved workplace conditions.

Steinbach - the pool specialist from Austria - is the domestic market leader for high-quality pools, including accessories and suitable pool technology. To ensure that the water quality remains permanently high, Steinbach produces the perfect water care products itself. Fine-grained raw materials are used as the raw material for the pool products. They are released into the air during processing and are distributed throughout the hall.

For Steinbach, a healthy future starts at the workplace

Sustainable procurement and the use of regional raw materials along the value chain is a key concern for Steinbach. The ecological footprint should be kept as small as possible and the focus is on a healthier future. And for Steinbach, this starts with its employees: in 2020, the production and wholesale company invested in the construction of a new office complex in Schwertberg. Subsequently, the aim was to significantly improve workplace conditions in the production halls. Steinbach wanted to reduce the particle concentration of airborne raw materials by up to 50% in order to increase the protection of employees in production and make the production halls cleaner. And with the help of the cooperation with Kappa, it has more than succeeded.

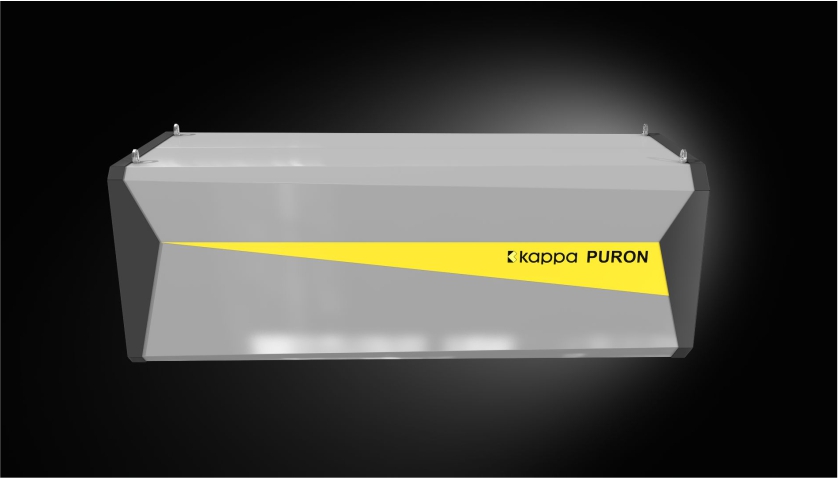

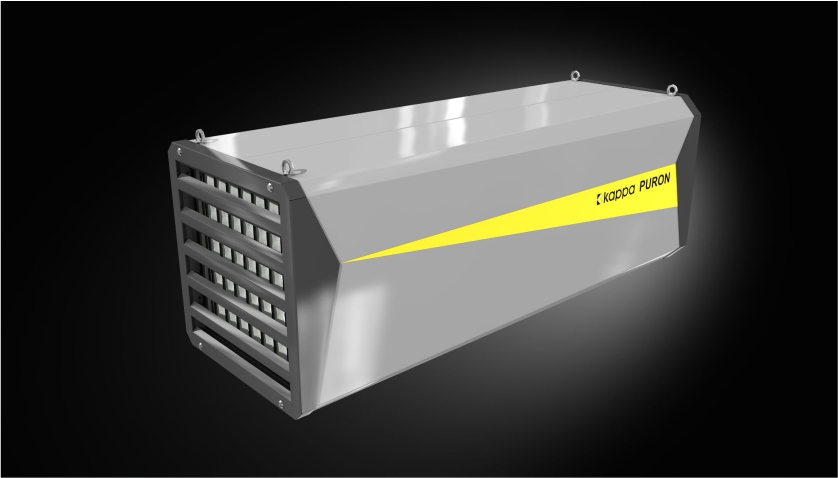

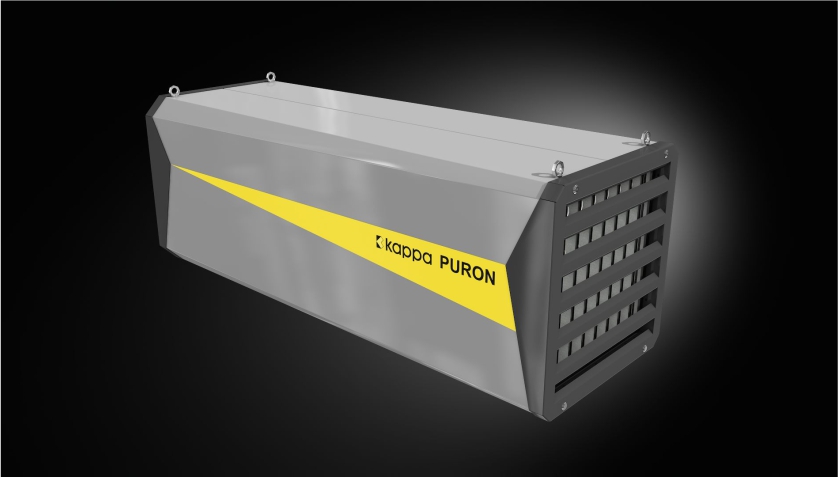

Measurably less particulate matter with the Puron® DX

This reduction needed to be verifiable on the basis of measurements. The company therefore defined five measuring points in the production hall at which aerosol and fine dust concentrations could be determined before the start of the project.

Kappa then installed four Kappa Puron® DX – room air filter, units in the production hall - a room air filter that was specially developed for the highly efficient separation of airborne fine dust particles. With minimal energy input, the room air filter cleans the hall air by separating an immense amount of particles and fine dust directly from the environment. This is done according to the “Dust Extraction” principle specially developed by Kappa.

The measurements after installation clearly showed that the project goal was more than exceeded: The Kappa Puron® DX reduces fine dust pollution in the work area by up to 93%. Particularly in the pressing room, where various chemical raw materials are mixed and formed into chlorine tablets, the particle concentration was reduced enormously.

Better production quality and lower cleaning costs

The installation protects employees, reduces cleaning costs and improves production quality. For the employees, the investment represents a considerable and immediately noticeable relief. Philip Brunninger, Plant Planning, Steinbach International GmbH on the success of the project: “One of our foremen came back from his vacation. He was immediately surprised at the improved air quality. When asked what had been done, his colleagues pointed to the Kappa Puron® DX room air filters above him on the hall ceiling.”

A Steinbach production employee also puts it in a nutshell: “In the past, a cleaning machine had to do the rounds here every hour and we were often coughing. Now both are history.”