When bag filters reach their limits: the time has come for Kappa Ekon®

Dust is released in numerous industrial processes. In addition to the composition and properties of the substance, the size of the dust particles is relevant from a health perspective. A distinction is made here between coarse dust and fine dust. This differentiation is also relevant for filter technology. As a rule, coarse dust can be easily separated using conventional bag filter technology. The efficient and economical filtration of fine dust is much more complex. Bag filter systems are therefore designed and operated with a low filter surface load. This further increases the already large space requirements of bag filter systems. If there is no more space where the emissions occur, modules have to be placed further away. This naturally increases the investment and operating costs.

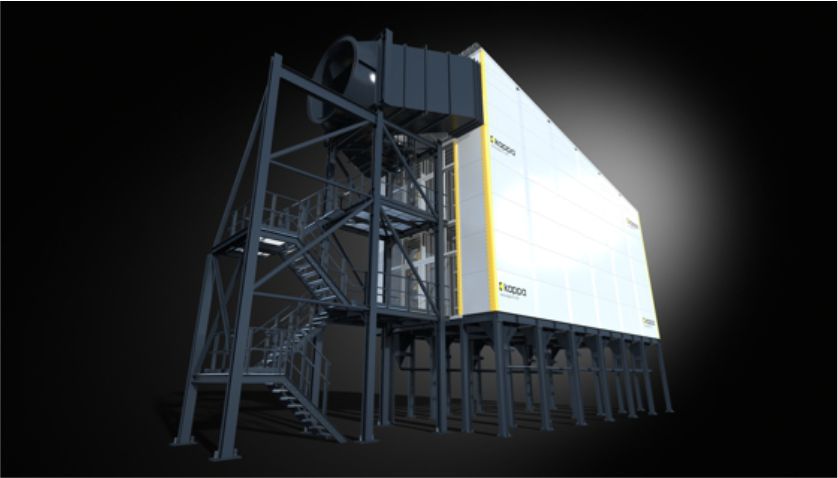

The new dedusting-system Kappa Ekon® offers an economical solution to this problem. Kappa Ekon® is an alternative to bag filters and is characterized by outstanding performance data. The space requirement is reduced by half and energy consumption by a third. The clean gas values are also improved by half.

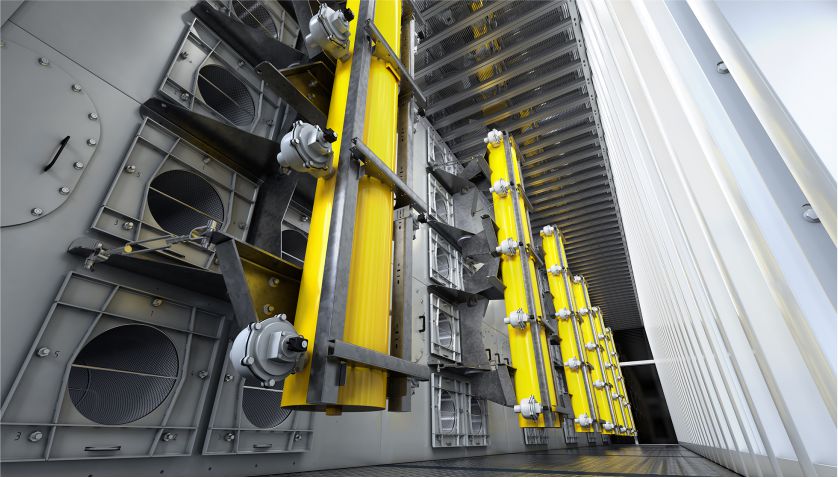

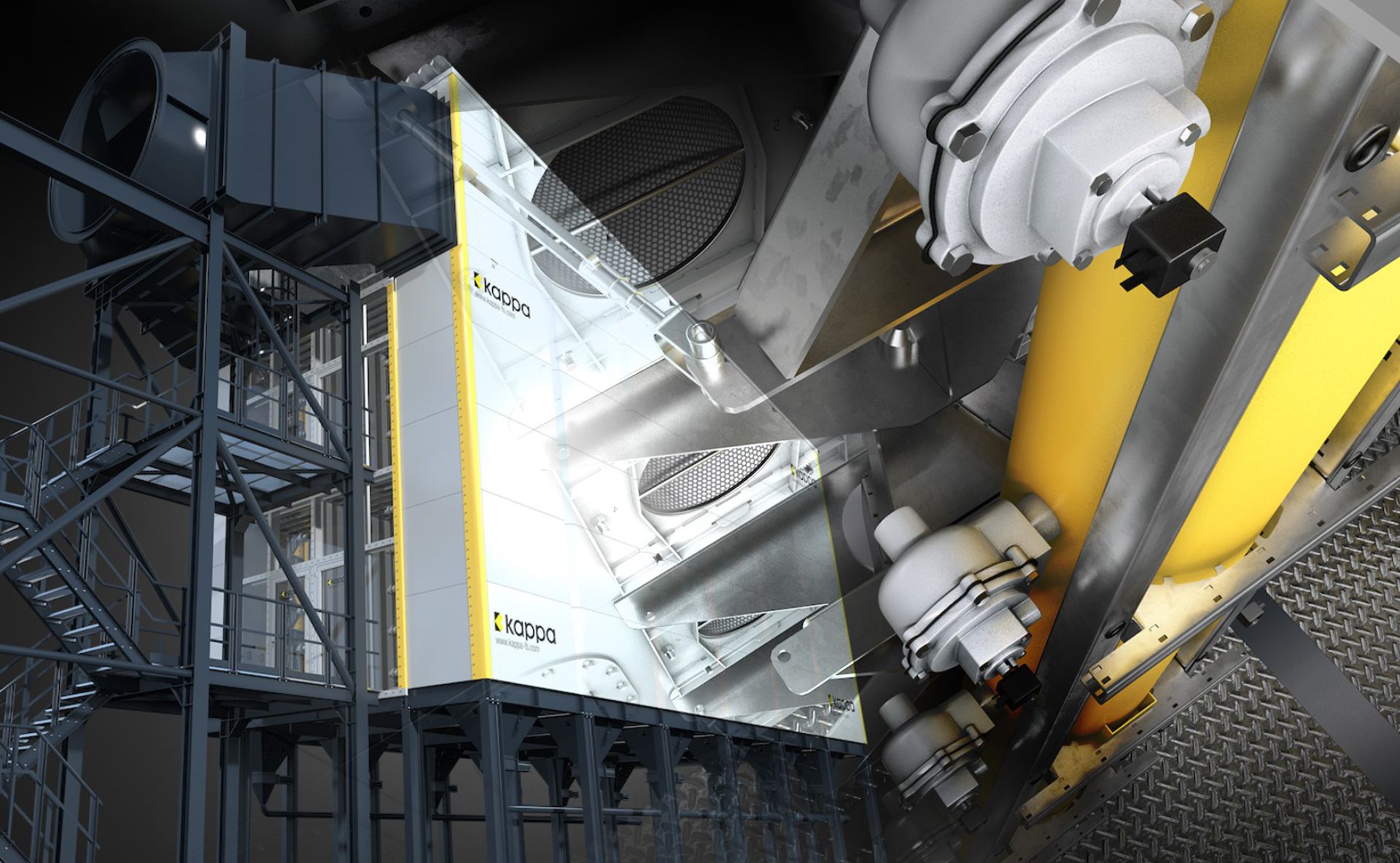

Thanks to its design, Kappa Ekon® enables compact separation of coarse dust and fine dust in one system. The technology is based on intelligent air routing in the filter system and the integration of raw and clean gas routing. The dust-loaded air is channelled into the filter in an energy-efficient manner so that coarse particles are already effectively removed here. The fine dust load flows evenly and at low velocity over the entire filter height to the filter elements. This concept means that upstream, external separation units - such as separation chambers or pre-separators - are not necessary. The combination of coarse and fine dust separation in one system reduces the space required and significantly increases separation efficiency. In addition, the investment costs and - thanks to the energy-efficient operation - the running operating costs are also reduced.

Modules ensure quick installation

In contrast to conventional bag filters, the Kappa Ekon® consists of precisely fitting modules. These are prefabricated element assemblies that are assembled on site using the Lego principle. This enables large dust extraction systems to be installed quickly, even on construction sites. Everything fits together perfectly, preventing leaks and malfunctions such as dust leaking into the clean gas area. The use of identical modules means that both medium-sized systems and large systems with an air flow rate of over one million cubic metres per hour can be installed in a space-saving manner. The required installation area can be reduced by half compared to conventional systems.

The intelligent design of the system results in flow-optimised air routing. Air intake and exhaust are integrated into the overall concept. In conjunction with the newly developed filter elements, the overall resistance is significantly reduced. The Kappa Ekon® reduces energy consumption during operation by around a third.

An example from practice

Using Kappa Ekon® , a clean gas value well below 0.5 mg/m³ was achieved. This corresponds to one fortieth of the required clean gas value according to the currently valid TA-Luft. With an exhaust air performance of 530,000m³/h, the power consumption is only 500kW. The previous state of the art technology required around 900kW. The space requirement has been reduced by 60 per cent.